3. Evaluation index of cryogenic valve technology level

In the design process of cryogenic valves, in addition to the general requirements such as the flow capacity and flow resistance of cryogenic valves, some other indexes should be considered in order to better evaluate the technical level of cryogenic valves. The technical level of cryogenic valves is usually evaluated by measuring whether the energy consumption is reasonable. The main evaluation indexes are as follows:

1.Thermal insulation performance of cryogenic valves

2.Cooling performance of cryogenic valves

3.Working performance of cryogenic valves’s sealing

4.Non icing condition of cryogenic valve surface

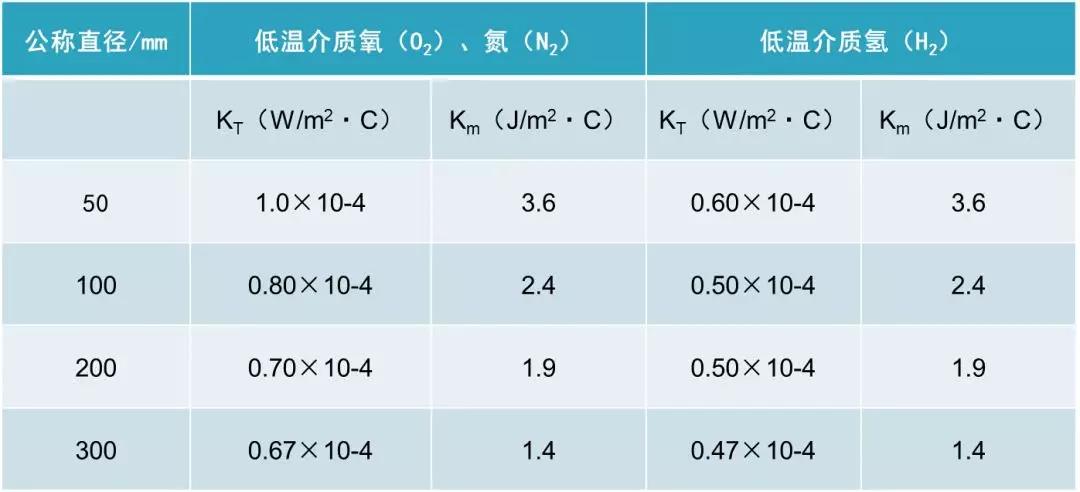

Table 1 technical level index of pneumatic vacuum insulated cryogenic valve

4.Material selection of valve body, valve cover,valve seat and disc

The selection principles of these main parts are as follows: when the temperature is higher than – 100 ℃, ferritic steel should be selected; when the temperature is lower than – 100 ℃, austenitic stainless steel should be selected; when the temperature is lower than – 100 ℃, the appropriate materials should be selected according to the lowest service temperature.

5.Material selection of valve stem and fastener

When the temperature is higher than – 100 ℃, the valve rod and bolt are made of alloy steel such as Ni, Cr Mo, etc. When the temperature is lower than – 100 ℃, it is made of austenitic stainless acid resistant steel. However, the hardness of 18-8 acid resistant steel is low, which will cause friction between valve stem and packing, resulting in leakage of packing. Therefore, the surface of the valve rod must be plated with chromium or treated with nitriding and nickel phosphorus to improve the surface hardness. It can also use thermal spraying process, surface spraying molybdenum, STL and other wear-resistant, corrosion-resistant alloy. In order to prevent the nut and bolt from seizing, the nut is generally made of Mo steel or Ni steel, and molybdenum disulfide is coated on the thread surface.

6.Selection of gasket and packing materials:

In the design of low temperature valve, on the one hand, the structure design is used to ensure that the packing works close to the ambient temperature, on the other hand, the low temperature characteristics of the packing should be considered when selecting the packing. Asbestos packing impregnated with tetrafluoroethylene is generally used for cryogenic valves.

Flexible graphite is an excellent sealing material. The material is impermeable to gas and liquid, and has 10% ~ 15% elasticity in the thickness direction, so it can be sealed with lower fastener pressure. It is self-lubricating and can be used as valve packing to prevent wear between packing and valve. The temperature range of flexible graphite filler is – 200 ~ 870 ℃.

Post time: Dec-01-2020